|

There's a little extra feature on my car that I have yet to see on another TVR Wedge...

Yes, it's cruise control! As far as I'm aware it was never offered by TVR as an option, but I thought it may come in

useful for those long drags down the motorway when my right foot has a habit of

getting carried away with itself...;-)

In the same way that the fuel

injection system was an 'add-on' for the SD1 (and the Range Rover), the Hella

GR65 cruise control system is a fairly simple collection of components that can

be easily liberated from a donor SD1. One or two items are not so obvious and

may be harder to get at, but if you do as I did and buy a system already removed

from the donor car, the hard work is done and you just need to make sure all the

bits are there! In my case they weren't, but more of that later...

In case you don't know, cruise

control works quite simply: you get to a speed that you'd like to maintain,

press a switch and the car maintains that speed. You can over-rule the cruise

by accelerating (for example, to overtake something) and certain safety features are

included to stop you doing something that could break the car, or yourself!

1. First off, you need a cruise ECU.

Packed with digital electronics (in a 1980's sort of way) the ECU performs the

calculations of road and engine speed and sends signals to the vacuum system to

adjust the throttle.

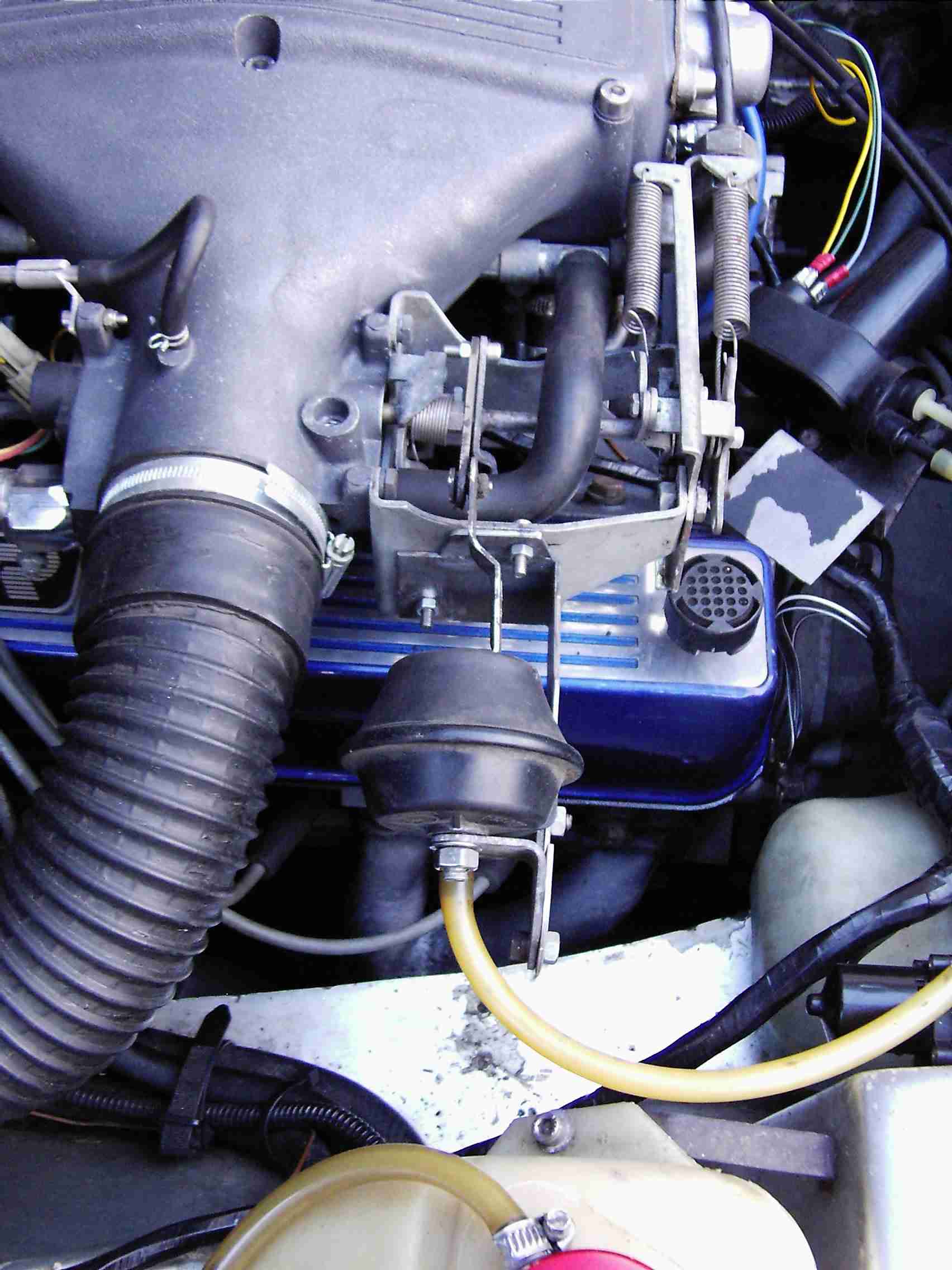

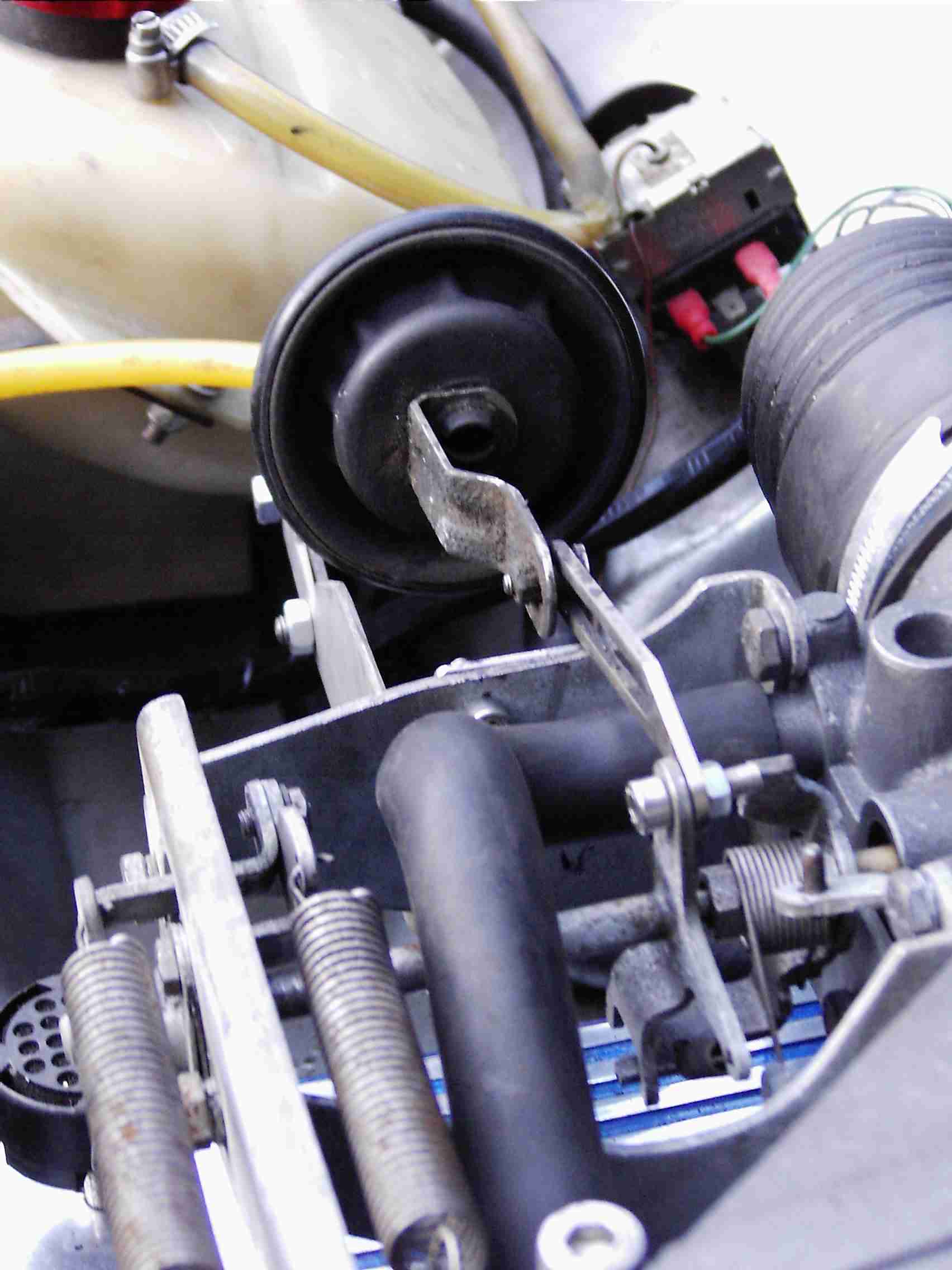

2. Vacuum system? Yep, there's a

miniature vacuum pump and solenoid valve that creates and controls the vacuum

necessary to operate...

3. The vacuum servo (or 'bellows');

which is linked to the throttle assembly by... well, a bit of stiff wire! This

was improved later to a slotted metal link. Age can cause the rubber to split and replacement bellows units can be found more easily on scrapped Range

Rovers as a lot of them had cruise control.

4. Of course the ECU needs to know

how fast the car is travelling; this is measured by a sensor mounted on the

gearbox that detects the rotation of the propshaft - this was my main

sticking point, since the electronic sensor drove the speedometer of the SD1 in place

of the cable-driven version. The older (Dana) cruise system of the early SD1 uses a small magnet

mounted to the output flange of the gearbox; as it passes the sensor a pulse is

generated that is fed to the ECU. The faster the prop turns, the faster the car

is going and the more pulses are generated (when I started looking into installing cruise I thought I may have to adapt this idea

to drive the Hella system, as the TVR of course uses a cable-driven speedo).

5. Steering column control switch.

As seen in the picture above. Tells the ECU when the cruise is required, when

it's not, and when it is again. Quite a neat solution, from a

retro-fitting point of view. A lot of cruise-equipped cars had/ have the cruise

functions selected by switches in the steering wheel. Luckily BL were cheapskates and on the SD1 did it this way instead :D The

only minor change was to the upper column shroud, which has a new cutout to suit

the cruise switch. It wouldn't be absolutely essential to have this shroud from

the donor, as the existing one could be modifed with care. The cruise switch has

its own mounting bracket which screws to two holes thoughtfully provided in the

rear of the indicators/dip/main/horn switch, so again, as long as you get the

cruise switch itself, the existing switchgear can be retained - as long as your

TVR has SD1 switchgear, that is, as late cars used the stubby switches from the Mk. 3 Granada. I have actually seen a couple of TVR

Wedges with the modified upper shroud, but no cruise. I guess TVR fitted

whatever they could lay their hands on that week... ;)

6. Overspeed relay. Detects ignition

pulses and cuts the cruise if the engine revs exceed a certain point: this stops

you engaging cruise in a high gear and over-revving the engine trying to get

there in a low gear! I think the limit for the V8 is 5400 pm, which in the TVR would be

something on the wrong side of 125 mph in top...

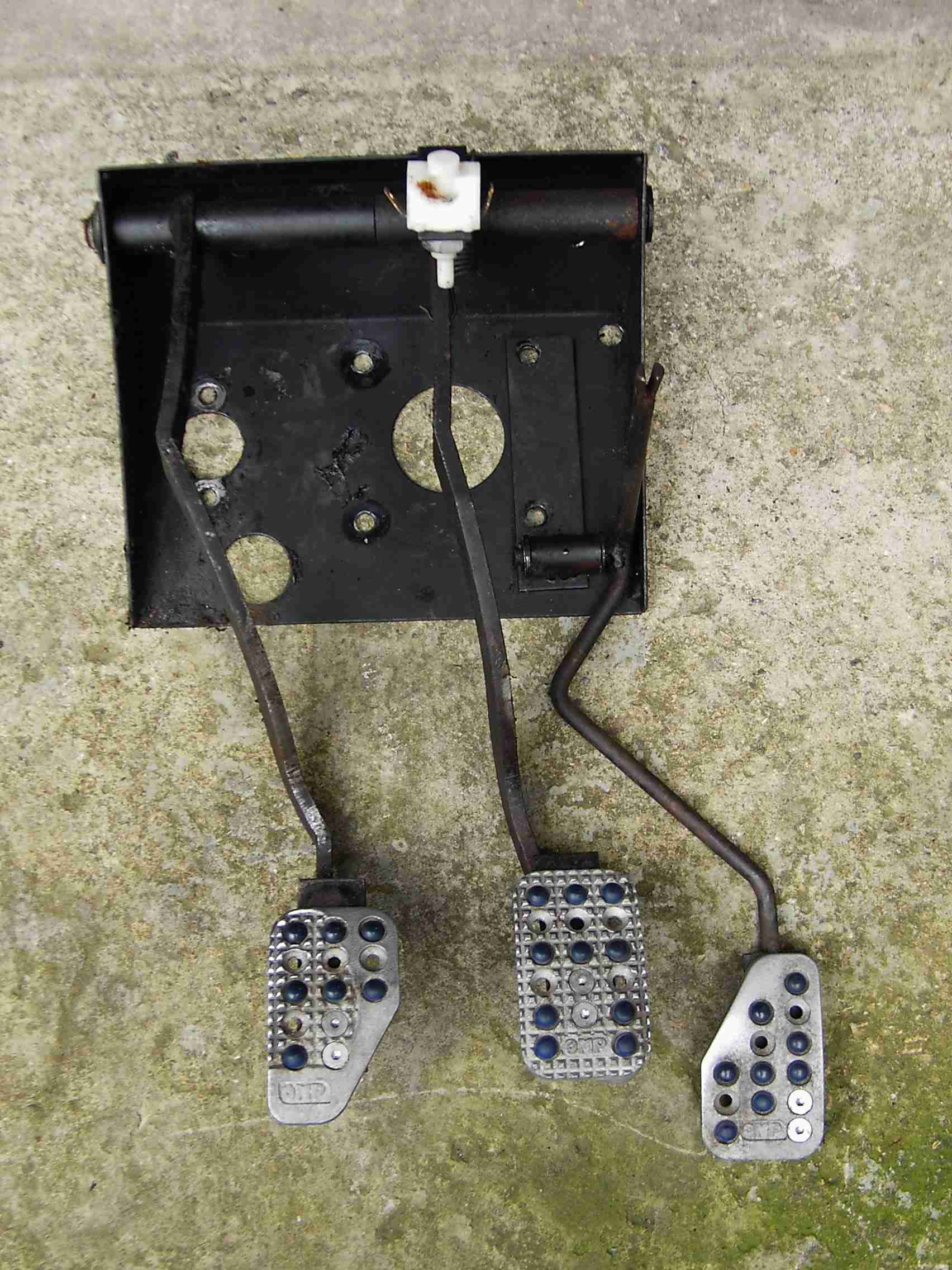

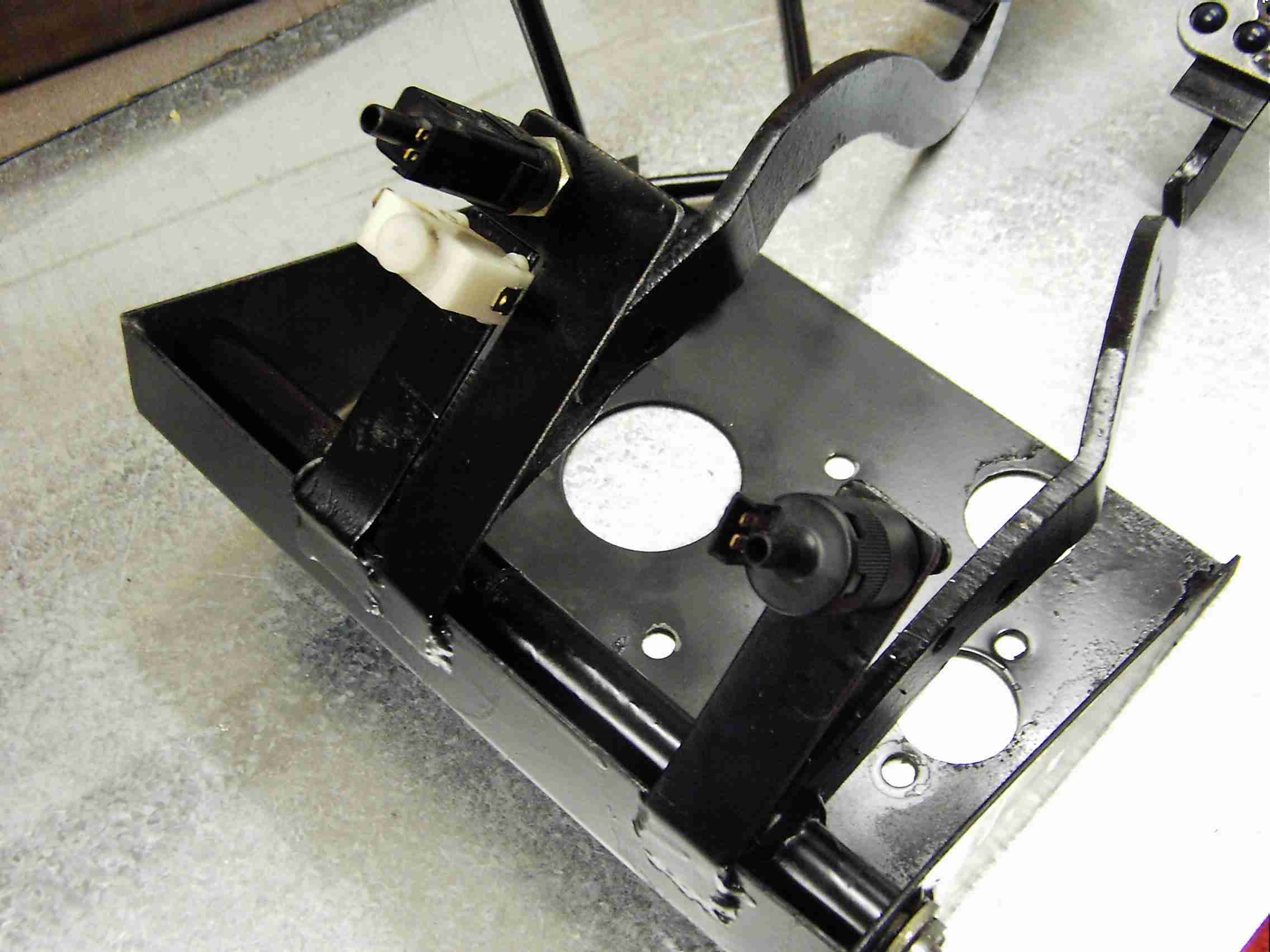

7. Pedal switches. Fitted to the

brake and clutch, these are cut-out switches that tell the ECU to release the

vacuum if either pedal is depressed (braking, or changing gear...) as otherwise

the engine would rev to the skies, or try to fight the brakes. As well as an

electrical contact, the switches also incorporate a valve that opens the vacuum

line to atmosphere, rapidly releasing the vacuum servo so the throttle closes

quickly, as opposed to switching the cruise off by the column switch which

slowly releases the vacuum to slow the car smoothly. Some ingenuity is necessary to mount the switches on a Wedge as the pedal box wasn't

designed with cruise control in mind.

8. Wiring loom and main fuse - as it

says, a dedicated section of wiring with all the necessary connectors and fuse

to supply the components of the cruise system.

A selection of brackets were also

used to mount the cruise components on the original car; none of them did what I wanted so they were all scrapped.

I assembled

the bits and pieces and established that they worked, which took a bit of

thinking about - I bypassed the overspeed relay; one wire has to be earthed to simulate connection via the brake

lamps - a safety feature: if the brake lights aren't intact then the cruise won't engage as it won't see a voltage change when you brake; the speed pulse generator needed a load resistor as

the electronic speedometer wasn't present... but apart from that it was simple enough.

I used a cordless drill to spin the

pulse generator; pressing the 'SET' switch caused the vacuum pump to fire up and

suck the bellows unit. Speeding up or slowing down the drill made the bellows

extend or retract just as it should.

So, how to fit the bits to the car?

The column switch was far and away the easy bit as it simply screws to the rear of the existing indicator switch. The pedal box needed

to come out to have the release switches fitted which meant dropping the steering column, the clutch

master cylinder, brake servo and half the wiring loom... but first I considered the bellows

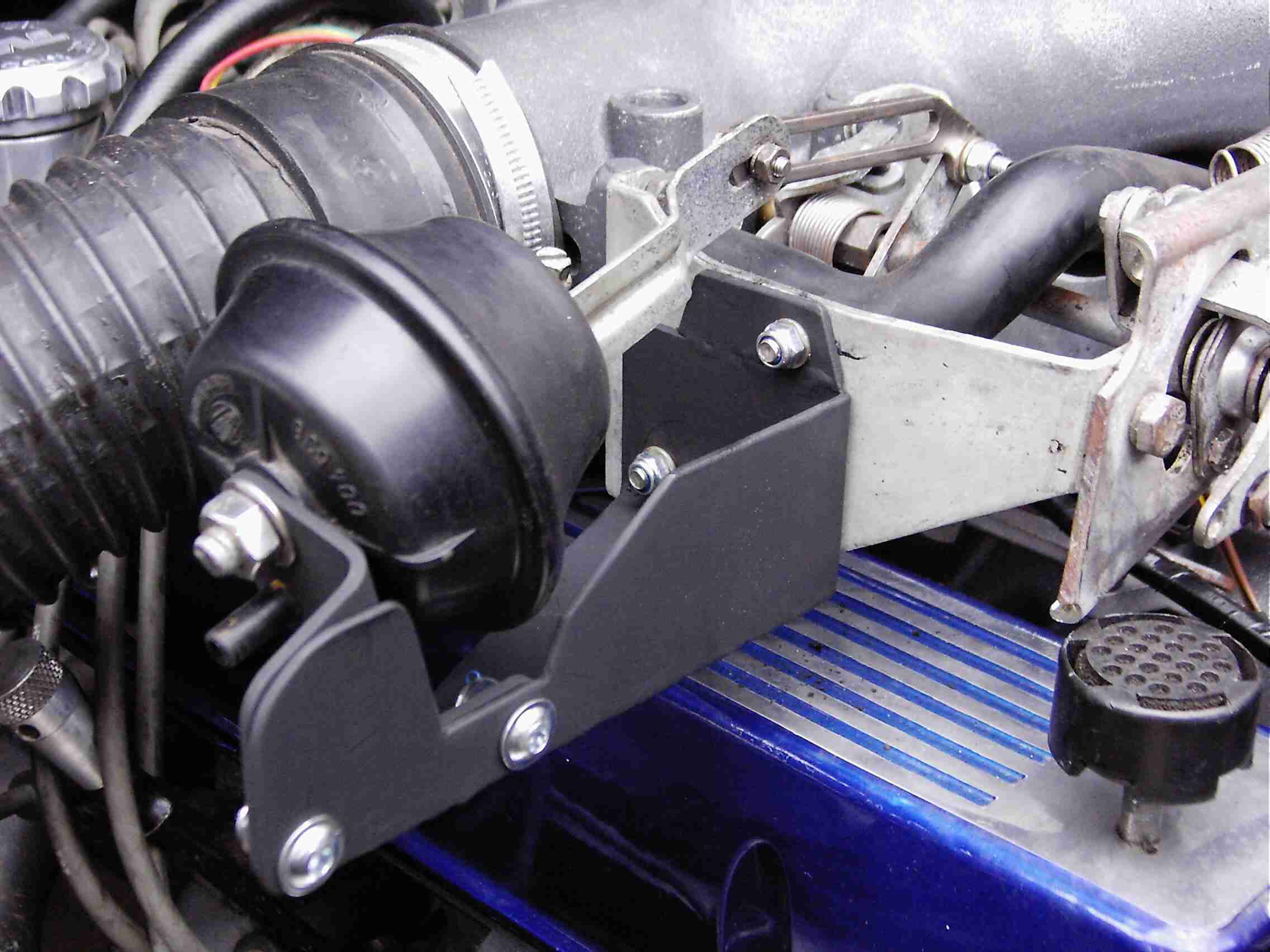

unit. There are two obvious points where the bellows could pull on the throttle

linkage, but only one of them seems to allow a proper arc of travel. So with a

bit of measuring and some guesswork, a piece of steel plate was cut and drilled

to support the bellows off the side of the existing steel bracket, using two

bolt holes thoughtfully provided:

The TVR uses THREE throttle return

springs. I wondered whether the vacuum pump and/or bellows would be able to pull

the throttle against such resistance. Firstly I tried sucking on the bellows and

that seemed to work OK, so I temporarily connected up the pump and applied

power. It worked!

Finally, I checked to make sure that

the throttle linkage could work through its full range without the cruise

linkage fouling it. All OK there. There was a slight flexing of the new bracket but not enough to prevent

the bellows working; later I added a welded gusset to stiffen the bracket.

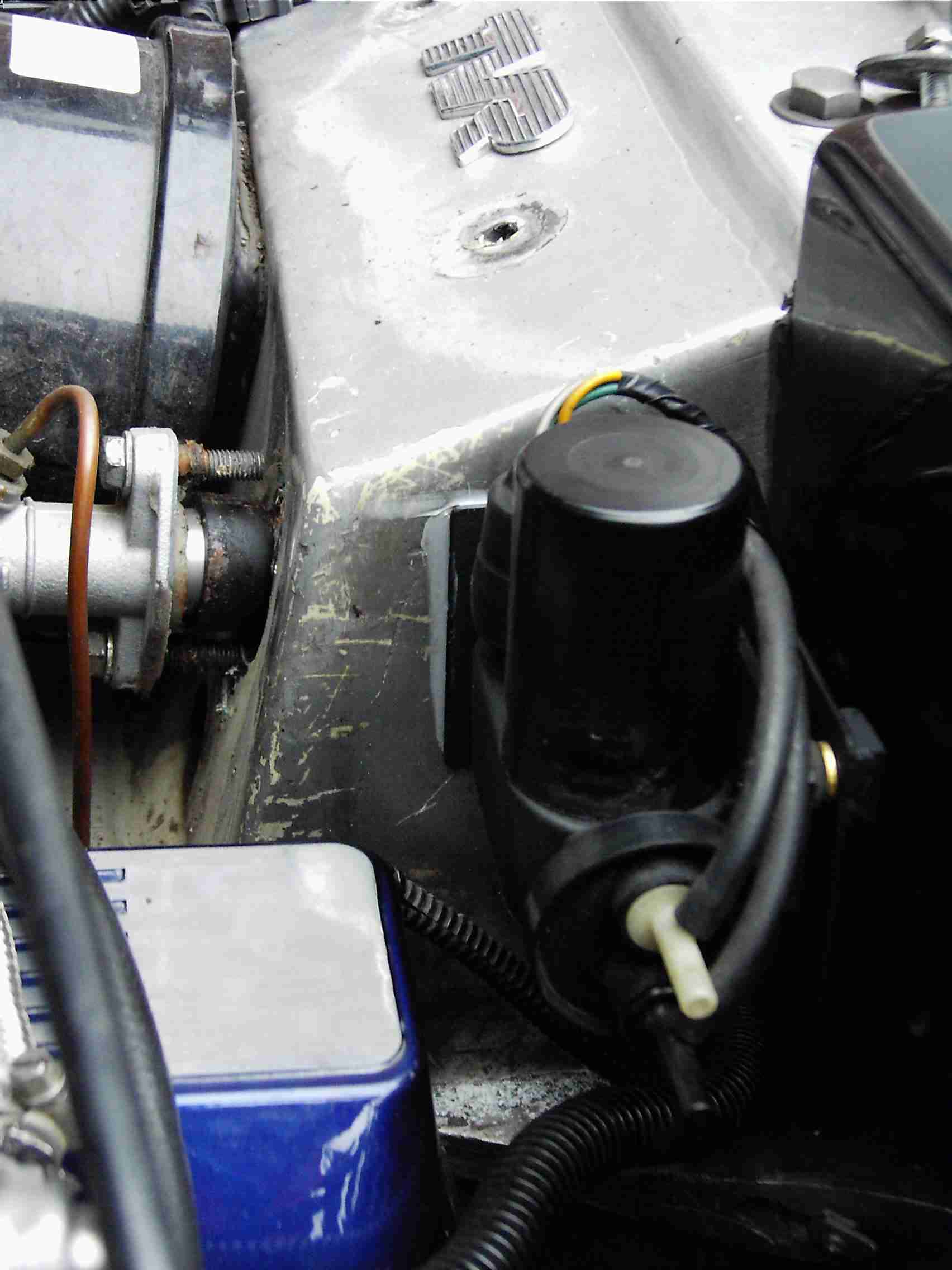

Next I pondered whereabouts to site

the vacuum pump. I settled on the inboard face of the GRP moulding that

surrounds and supports the pedal box. This position keeps the pump out of the way of just

about anything that I'd be likely to need access to, whilst leaving it handy for

electrics and vacuum pipework. I tried the original mounting bracket every which

way but couldn't make it fit so I gave up and fabricated one - a simple L-shaped

affair - with captive threads for the pump mounting screws.

It was obvious that the pedal box would have to come out.

There was no way I was even going to attempt to weld brackets to it, down in the

depths of the footwell. Luckily I had a couple of days off work. It looked like

I might need them...

As it turned out, it wasn't all that

difficult a job. Before you can extract the pedal box, the steering column needs

to come out. This means disconnecting the upper universal joint in the wheelarch.

Disconnect all the multiplugs from the column switchgear (snipping cable ties as

you go!), remove the two nyloc nuts holding the clamp to the support strut and

the column should drop onto the driver's seat. At first glance it looks as

though you could unscrew the column clamp knob from the rake/ tilt assembly and

drop the column that way, but there's a cunningly-placed roll pin to stop you

removing the clamp bolt. Once I had the column out I knocked this out and

replaced it with a split pin in case I ever need to drop the column again.

Here's the roll pin:

The column with it's mounting and

rake/tilt clamp:

Eagle-eyed readers will spot that

the lights switch appears to be upside-down: you can pull the lever off and

invert it. The rusty elliptical thing at bottom left is the bush that

supports the column where it passes through the footwell; there was a bit of play

so it needed replacing. More on that

here...

Four nuts hold the pedal box to the

brake servo; two more secure the clutch master cyl.; two bolts hold the box to

the scuttle/firewall (the ones just above & behind the brake servo when seen from the engine

bay). Two of the servo nuts retain the throttle pedal on a separate bracket; the

throttle cable needs to come out as does the bonnet release cable and the speedo

cable. With the clutch and brake pushrods unclipped from the pedals and the

brake light switch wires detached, it was just a matter of wriggling the pedal

assembly out from under the dash (apologies for the chav-tastic pedals, previous owner's doing!):

Although the steelwork had been

plastic-coated there were a few patches where clutch fluid leaks had removed the

coating. I took the opportunity to sandblast and repaint these areas and also

the pedals themselves. I played around with the cruise release switches and

fabricated some simple brackets (in the style of the existing brake lamp switch

mounting) to locate them. These were duly welded and painted, then the unit

reassembled with fresh grease.

The white switch is the brake lamp

switch and the other two are different versions of the Hella release switch. The

simple strap brackets allow the switches to be adjusted relative to the

pedals. As an aside, the Tasmin designer, Oliver Winterbottom, mentions in his autobiography 'A Life In Car Design' that the pedal box was 'TR7-based'. By chance I found somepne selling a TR7 pedal box on eBay and whilst they're similar, the TVR version is simpler in that it doesn't have a rolled edge surrounding it. I guess TVR probably just used the pedals and shaft and kept the sheet metalwork simpler - the Triumph version was probably banged out by the thousand on press-tooling which allows fancier shapes. Or perhaps TVR cut off the bits they didn't need...

Whilst the paint was drying I took

the opportunity to mount the vacuum pump

using self-tappers, with a smear of silicon sealant to keep the water out:-

The vacuum servo almost looks

like the factory fitted it! I got my paint cans mixed up: the finish was supposed to be satin

black, not matt. You can see the slotted link that allows free movement of the

throttle linkage when not in cruise mode:-

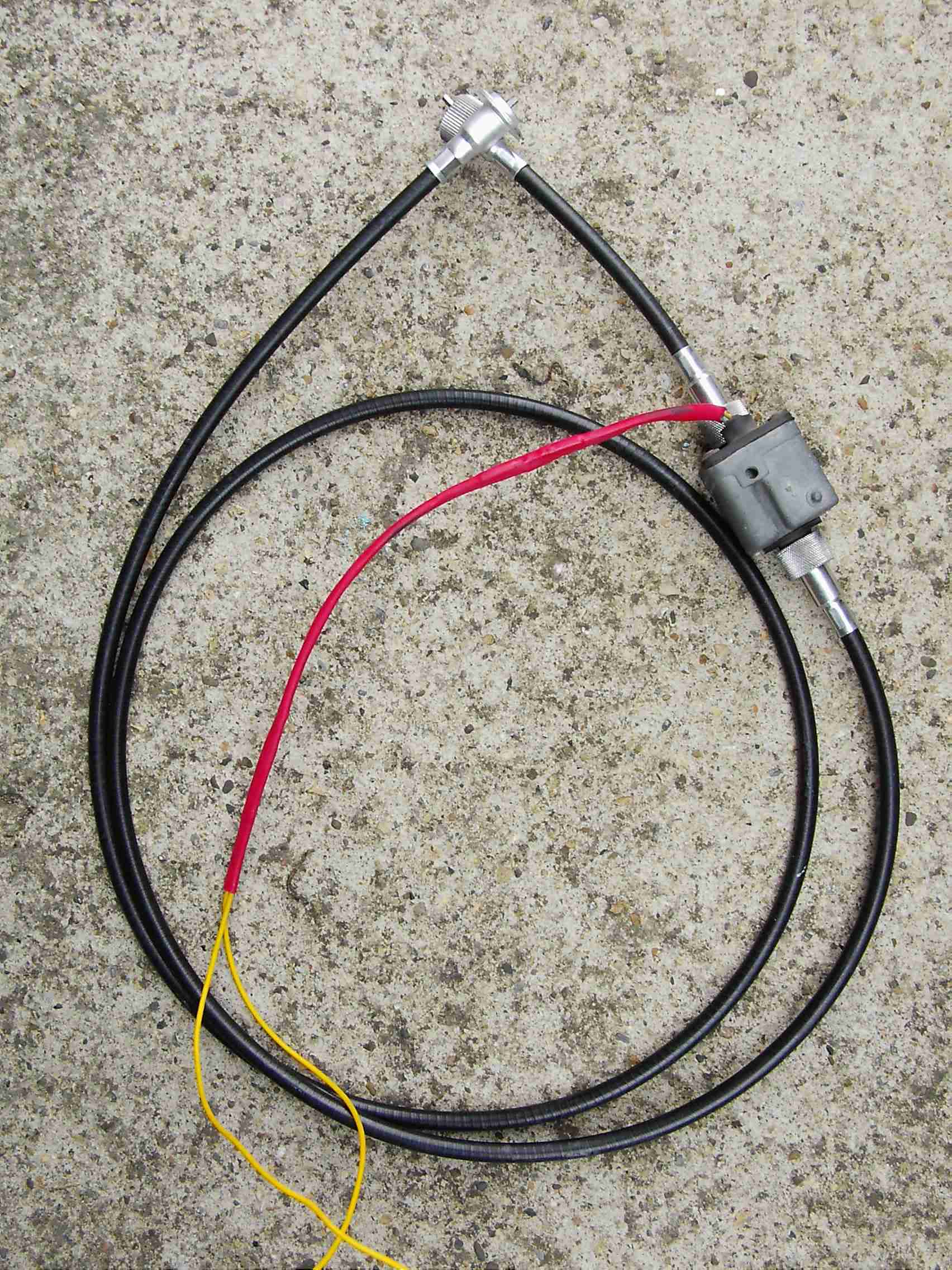

The remaining stumbling-block was how to provide the electronic pulses

that the cruise ECU needs to know the vehicle's speed. The earlier SD1s (and the

TVR) used a cable-driven speedometer, whereas the later SD1s gained an

electronic instrument pack that included fuel economy information. This used

a sealed pulse generator that was fitted to the gearbox in place of the cable

drive. I could use one of those but then I'd lose my speedo. I'd seen a couple

of later TVR wedges that used an electronic pulse generator fitted in-line with

the speedo cable, but they were used to feed speed information to the fuel

injection system ECU to aid the idle stabilisation. Then I discovered that some

Range Rovers used the same pulse generator, so of course I HAD to get hold of one to try.

One rummage on Ebay later and the pulse generator was installed to the system

and spun-up with a cordless drill. It worked! The SD1 electronic generator

normally used with the Hella cruise system is a 'proper' sealed bit of

electronics where the (Jaeger) device from the Range Rover is simply a

magnet spinning in close proximity to a reed switch. Whether this would cause

issues, e.g. with contact bounce would only become evident over time. I plumbed the vacuum lines in using 5mm airline tube and push-fit connectors; should be OK for vacuum as the pump will compensate for any leaks!

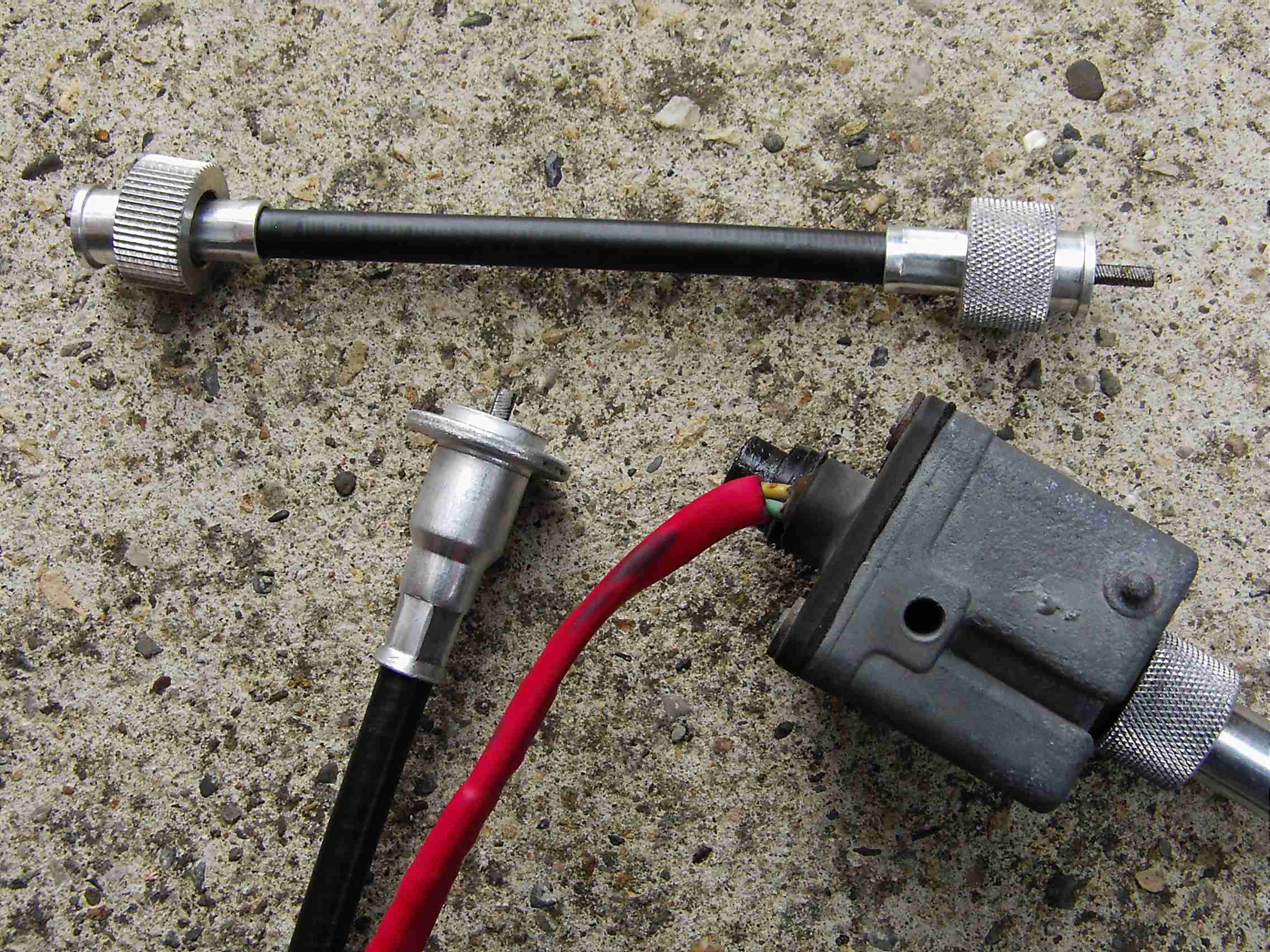

Needless to say, the combination of LT77 gearbox and VDO instruments on the TVR results in a speedo cable that appears to be incompatible with anything from any car manufacturer in the known universe, let alone anything that would have a split cable. I'd heard about Speedy Cables so I fired off an email to see if they could make me something; the reply was positive enough that I chucked the old cable plus the speed transducer into a Jiffy bag and sent it winging Wales-ward. A fortnight later another Jiffy bag returned, containing exactly the right bits to do the job! From my recollections of other Wedges I'd seen with the same speedo transducer, it was fitted into the cable in a position that left it in the engine bay. I asked Speedy Cables to position it just a few inches from the speedometer end so that it'd remain in the cabin - hidden behind the dashboard.

The only slight hiccup was with the knurled nut that secures the upper cable to the rear of the speedo: the nut was too deep and wouldn't pull the cable firmly against the speedo boss. A few seconds dressing with the bench grinder easily reduced the depth and the cable nipped up securely. Pic shows the cable before doctoring, it's the nut at left end of the short cable that needed work:

To make access easier I whipped out the split pin mentioned above and dropped the steering column onto the driver's seat. The lower bearing protested a bit as it had to move in its housing to accommodate the movement but it coped OK...

The ECU and overspeed relay were simply mounted (read: shoved) behind the centre radio console. This left the wiring loom nicely positioned so that it ended under the instruments. I had to run two wires across the cabin to the passenger footwell; one ties in to the ignition pickup feed that triggers the fuel injection and the other I spliced in to the boot lock fused feed (can't see me trying to 'cruise' and open the boot at the same time!). The brake and clutch pedal switches were wired in series; the column switch simply plugged in. Suddenly... it was finished! Time for a drive then. I took along the wiring diagram, multimeter and spare fuses but I needn't have worried. I hit the local dual carriageway and sat at about 40mph. I pulled the stalk towards me to energise the cruise system. Then I tapped it upwards to 'Set' and slowly lifted my foot off. With just a slight surge the cruise control took over and I was able to test the controls. Below about 35mph the throttle response gets a bit ragged, it's rather on/off, on/off... but that's hardly where you'd use cruise. Up at 70/80 mph it's spot-on. Mind you, exiting a roundabout in second gear and hitting 'Resume' when you were just doing 80 gets interesting... 8^0

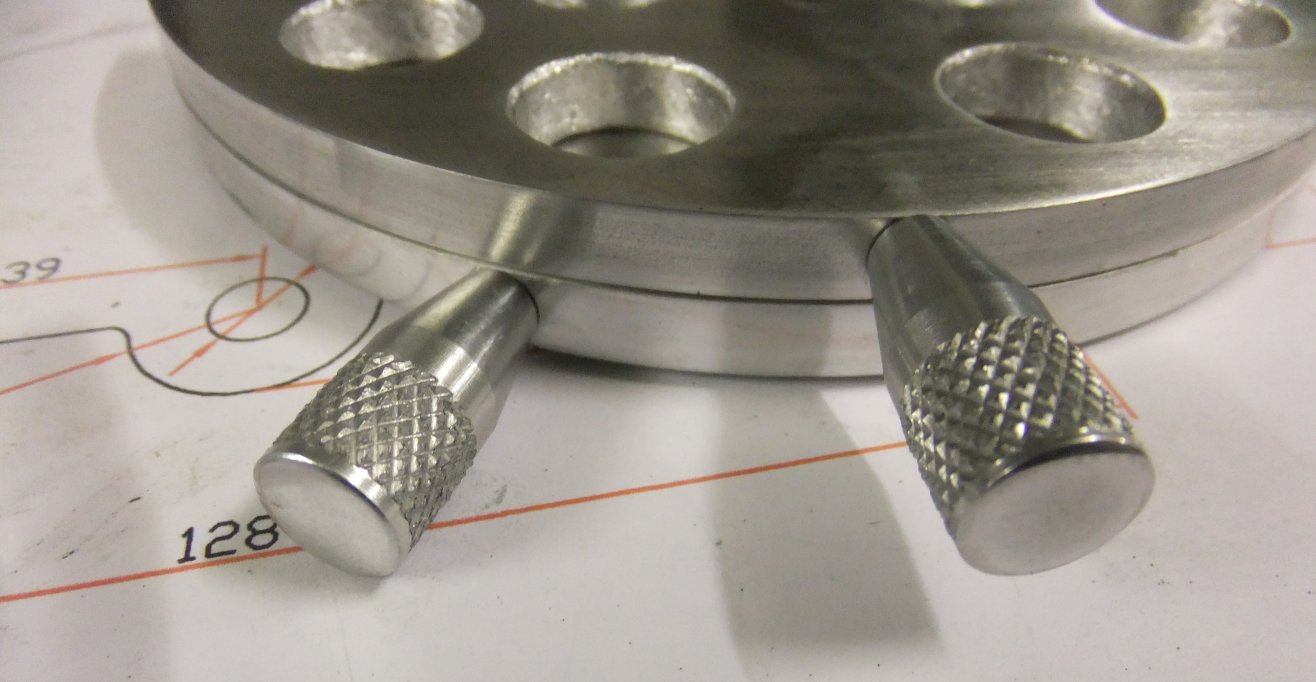

Meanwhile, I'd pondered a few times over the spindly column switches that TVR robbed from the SD1. With the 390's smaller steering wheel, the stalks stuck out some way either side and the indicator lever was forever getting stuck against the radio console! What was needed, I thought, was some shorter stalks. Preferably not spindly. Preferably more 'in keeping' with the other cabin accessories, like the alloy gearshift knob and alloy handbrake. I know! I'll make some new stalks... out of alloy :^D

Now I'm by no means a skilled machinist so attempting to replicate the existing switches with their push-button ends for horn and screenwash was a non-starter. What I needed was some ready-made pushbuttons, around which I could design the 'stalk'. I duly found some stainless steel pushbuttons that have threaded bodies. Some aluminium bar was then bashed about on the lathe - drilled, turned, bored, knurled, threaded and generally reduced to swarf on the floor - resulting in these:

I think they're still a bit long (though they're an inch shorter than the SD1 originals) so now I know what I'm doing (ahem) I'll have another go. Of course I'll need to make another one for the cruise control as well! Here's the new switchgear on the car:

...and with the alloy gearshift and handbrake:

Then I thought... those heater controls might look better in aluminium.... :^D

... and indeed they do:

The large holes are in response to someone who pointed out that I was adding excess weight to the car...!

Meanwhile, a fellow Wedge owner had spotted my alloy switchgear at a TVR meeting and persuaded me to make him some for his early Tasmin (known in Wedge circles as 'Delilah'). The Tasmin used Trumph TR7 column switches and the levers were more bent than those on the SD1, but with some care I made these for him:

Delilah's changed hands a few times in the last few years but when last spotted for sale she still seemed to be sporting my handiwork :D

UPDATE 090918:

I finally got my act into gear and remade the column stalks. The latest incarnations are a good bit shorter than the first versions (although the indicator would be better if it was shorter still) and this time the pushbuttons aren't recessed but slightly domed, which in the case of the horn is a bonus since you no longer have to poke at it with a fingertip. I wanted the wiper stalk to be bent a bit more as well, since it still points slightly down at an angle in the 'off' position whereas I really wanted it horizontal. Just a small thing... in fact it's because it's so small that I couldn't bend it!

Then there were the heater controls that I'd made (a few inches up the page but a few years back in time). I decided it was high time to fit them, so one fine afternoon in late summer 2018 I pulled the centre console apart and removed the old plastic heater dials, sliders or whatever you want to call them (yes, another TVR bodgification):

At which point I realised that they're not as identical as I'd thought (and made the alloy ones)... the left-hand one in the pic controls the hot water valve and the anchor screw for the control cable is closer to the pivot point than on the other (diverter flap) lever. This has the effect of reducing the range of travel of the control in relation to the range of movement of the valve, so all the travel on the alloy replacement was to one side of centre. It was a simple fix: I replaced the 'tab' of the control with a cranked one to shift the operating range. The new controls are a lot easier to operate than the originals and I don't think they look too agricultural... but then again, maybe the knurled finger-grips could do with being a bit smaller.

Now I'm looking at that mirror joystick and thinking it looks a bit... well... plasticky... ;O)

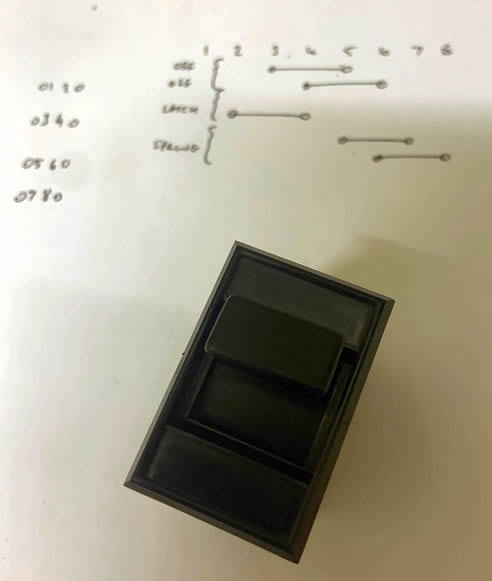

There's also that annoying switch blank, to the right of the hazard lights switch. I think that on a fixed-head car it would be the rear screen demister, but the soft-top 390SE of course doesn't have one in its plastic rear window. As an aside, car audio has come on a hell of a long way since the late 1970s and back then, an automatic telescoping car aerial was a rare thing. In order to be able to listen to the JY Prog, The Archers or What's My Line (I'd have said Jimmy Clitheroe but I think he'd died by the time the Tasmin was launched!) therefore, it was first necessary to extend the 'mast' by means of an up/down switch on the dashboard. The Tasmin fixed-head used the rear demister as its radio aerial, an idea which was later used (and rather more successfully, it has to be said) by a number of other car makers (including, I think, Ford on the Sierra, soon after the Tasmin). The Tasmin used a 'Bifi' filter unit to split the radio signal from the demister heating current. Anyway, back to the switch blank... elsewhere on the site I think I noted that I'd fitted an ex-RangeRover over-run cutoff switch, an item which wasn't standard on the ex-Vitesse engine used by TVR. The switch is actuated by high manifold depression, typically when decelerating, and triggers a relay which breaks the injection ECU's input signal from the ignition amplifier. You'll recall that the ignition trigger signal is the only thing that tells the ECU the engine is running. When the switch triggers, the relay effectively turns off the fuel injection. Whilst it undoubtedly saves (some) fuel, it also stops the engine popping and banging on the over-run (not what you want in your Rangey, down Chelsea way). Now I know it's fashionable for today's 'yoof' (and not-so yoof) to fanny about with their shopping cars' fuel maps to deliberately induce the Rice Krispies (snap, crackle and pop...) but it's just a bit... well... twatty. Come on, it is, really. Yes it is :D You can forgive the Rover V8 for it; it was 40-odd years ago. That said, there are times when I'd rather it didn't do it, such as heading home through the local village late at night, hence fitting the vacuum switch. However... for the days when I really do want the car to sound like the monster it isn't, I fitted a switch under the dasboard so I can take the vacuum switch out of the equation and restore the 'factory' setting. Then I thought, why don't I fit a matching Lucas switch in place of the blank. And THEN I thought, it would be nice to be able to prime the fuel rail before cranking the engine (the later hotwire injection did that automatically - and yes, I know I could just fit a timer relay) - so why not fit a three-position 2-pole switch that could perform both functions? Well firstly there are only a couple of options for 3-position switches in the Lucas 182SA series; one is the heater fan, which is OFF - ON - ON and one is the window switch which is (ON) - OFF - (ON), i.e. the switch is only ON for as long as you keep your finger on it. What I reckoned I needed was ON - OFF - (ON), where the latching ON brings the vacuum switch into play and the momentary (ON) runs the fuel pump. No such switch in the range, of course. So I made one. First I needed an electric window switch, and that version is probably the rarest of the series.But after months of searching, a chance rummage through Ebay turned up another contender: it's a 3-position centre-off used on (I'd guess) the BL Princess as an oil and lamp check.

Unfortunately Lucas modified the lever to have a bulbous end on it and although you can remove it easily enough, the lever underneath is not pretty. So another lever is needed, which means finding another switch from the range. As it happened I already had a spare (demist, ironically) switch which, whilst not having the same 'ribbed' lever end as the rest of them, looked better than the ex-Princess version.

So I stripped both switches down and tried to work out what needed to be done to give me one latching and one momentary position either side of the centre-OFF. It turned out to be very simple: swap one of the copper contact strips of the 3-way switch for the single one in the demister switch. The shape of the contacts is what determines whether it's a latching or momentary function, while the main switch body is moulded to allow the correct amount of travel for the number of positions, as seen here in a back-to-back comparison. It should be obvious that the lever on the right-hand switch can't depress any further (it's a 2-position body).

I also swapped the outer bodies over, as the ex-Princess type had the painted silver trim line around it which wouldn't match the car - the demist switch outer body was plain. I then polished the demister symbol from the end of the lever. All the remaining bits were reassembled into a single-throw 1-pole non-latching (i.e. OFF - (ON) ) that will probably confuse the hell out of me some years down the line when I find it in a box and wonder what it does! Now, if I could only find the correct Lucas connector to fit the modified switch...

Back to top

Back to Wedges

Back to Home

|